The Rise of the Industrial App

“If you try to be everything to everyone, you’ll be nothing to no one.” – Unknown, perhaps the author?

This quote seems appropriate to describe most large enterprise software solutions through the eyes of this operator. In any of my prior lives, which one of my enterprise software did I get the most value from, do you ask? Silence ensues – you get the picture. Whether it’s ERP, MES, QMS, WMS, etc., these were all one-way streets. I’d input data periodically, as I was taught to do, and apparently that data went somewhere useful. Who knows? Maybe Accounting was the beneficiary. Maybe Compliance. Someone outside of my operations circle, that’s for certain.

The current reality

The issue facing those in charge of operational value creation is how to access the information necessary, from the available set of tools, to drive positive change in the organization. Despite the widespread adoption of some heavy tools over the last 20 years, this process is still done mostly on spreadsheets today. Let’s say you’re doing an operational due diligence. The starting point is a data room filled with extracts from all of the major enterprise systems. Then, you work tirelessly using a spreadsheet model to identify the useful pieces of information and plug them into your model to create an output that can be used to understand how to impact the business. Take something as “simple” as product line profitability. I’ve never seen this done without the help of a spreadsheet making sense of disparate information coming from various combinations of ERP, MES, WMS, LMS, etc. The fact of the matter is that enterprise software has historically ignored the operator.

Where are we heading?

Operational intelligence vs. measurement

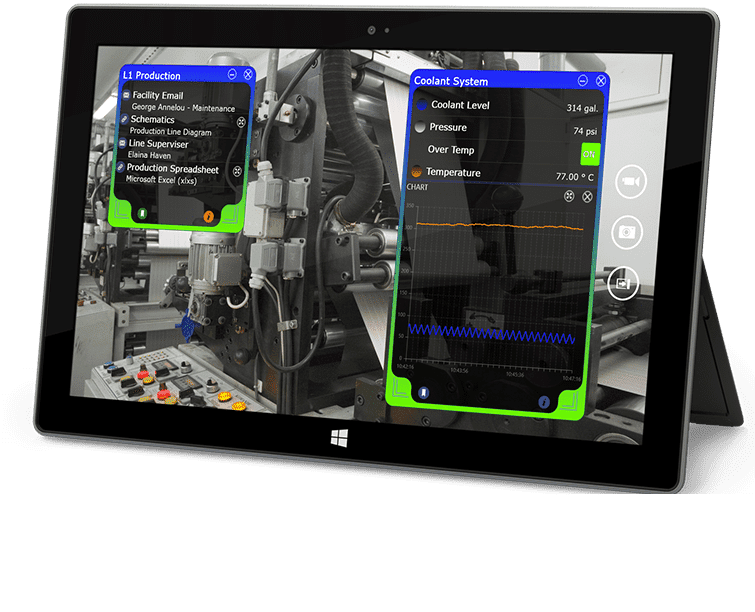

We’re now in the early stages of industrial technology moving beyond mere collection and measurement. The true breakthrough lies in the establishment of the “intelligence layer” within the IoT stack. This may often be conjoined with the full spectrum of IoT capabilities but it doesn’t necessarily have to be. The intelligence layer is becoming the data sponge in the new IT ecosystem. It’s the new platform for value-add interfaces that deliver value add to the appropriate shareholder.

In many ways the future ecosystem will resemble the evolution of human civilizations – new infrastructure resting on the shoulders of prior civilizations lost to memory. We will not uproot the legacy systems but rather build more useful layers on top of them. They will feed the intelligence layer but take their rightful place behind the scenes.

The industrial app

The intelligence layer ushers in the rise of the Industrial App. The Industrial App becomes the custom solution to the specific operations use case. Entrepreneurs and investors shouldn’t fear the Industrial App due to concerns about “scaling the point solution” or other similar concerns that have historically challenged software companies. This isn’t enterprise software and won’t behave the same way.

At Veryable, we believe that the age of the operator is upon us. The Industrial App finally becomes the vehicles by which we equip operators with the tools to drive value creation. As laid out in a prior blog called Digital Manufacturing, these tools will drive all of the use cases within the digital operations umbrella: predictive maintenance, labor optimization, asset utilization, material flow, etc. These are the use cases that stack up to create an operational competitive advantage and access the lion’s share of value creation opportunities still left on the table.

Previous Posts

Reading the Signals: Why Logistics Feels Early-Cycle Shifts Before Manufacturing

Build a Workforce That Scales With Demand

Create your free business profile and begin building your on-demand labor pool today.