Critical Chain Project Management: Buffer Reduction

Maybe you’ve heard of critical path project management, but what about critical chain project management? You might be wondering what the advantages could be of this project management approach.

What we’ve seen is that all manufacturing, distribution, and logistics companies share the constraint of labor, and most (if not all) of them have larger buffers than they would like.

Veryable created an on-demand labor marketplace to solve these problems by allowing businesses to build flexible labor capacity, but we won’t spend time here talking about the specifics of our platform.

Instead, you will learn from this article what critical chain project management is, how labor fits into this framework, and how you can reduce all buffers identified through your critical chain project management analysis by using on-demand labor.

Critical chain project management defined

Critical chain project management takes the established critical path approach to the next level by considering resource constraints in the project plan. This project management style is an application of Eliyahu Goldratt’s Theory of Constraints as a project management method. Goldratt defines the application of this approach through his novelization titled “Critical Chain.”

With this method, properly managing projects is no longer just about time; you must also account for the true capacity of your operation. Labor is usually the primary constraint, so we will focus on your labor capacity in this article.

Critical Path Project Management + Consideration of Resource Constraints = Critical Chain Project Management

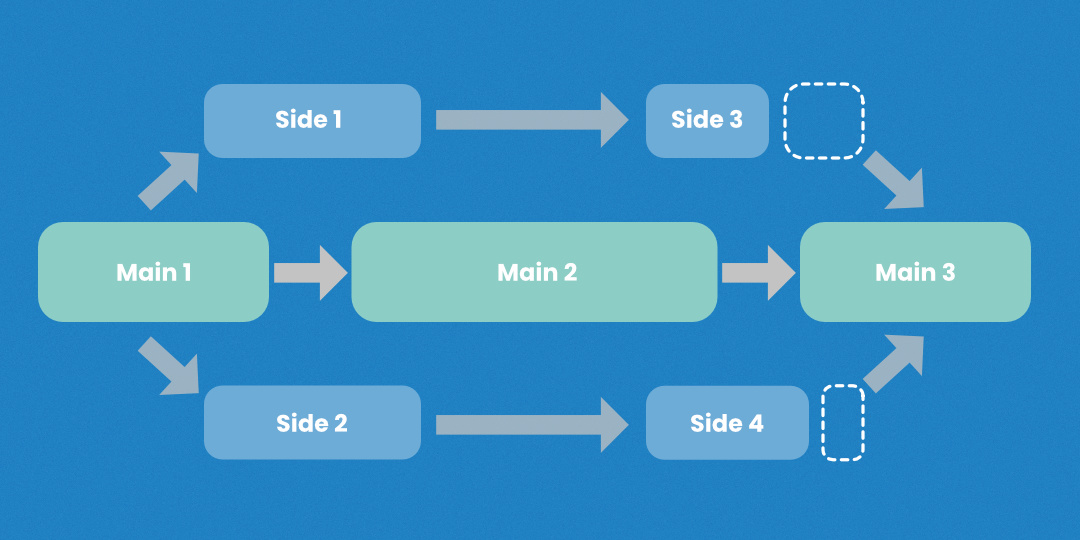

Once you’ve identified the critical path in your value stream, you need to take a look at the resources required to move value along the critical path and any feeding paths. Using this information, you will create a mapping of your critical chain that shows these paths and their required resources. This practice will identify the duration of the project buffer and the feeding buffers to de-risk project completion date.

As you create this mapping, you will probably identify the complacency of big buffers that are going to slow you down. These buffers are probably larger than they have to be, and show you where there’s room to cut feeding buffer tasks and place an incremental amount into the overall project completion buffer.

Buffers and what you should do with them

Buffers, which are there to help prevent you from overpromising and under-delivering, represent opportunities for improvement. Although many project management methodologies emphasize the need for some level of buffer, ideally you’d have as few buffers as possible. This is because buffers are a way of coping with inefficiencies, unpredictable events, and limited resources.

There are three types of buffers in critical chain project management:

- Project buffers - added to the end of the project as a catch-all contingency for critical chain activities

- Feeding buffers - added between non-critical feeding chains and the critical chain

- Resource buffers - in the critical chain to give time to ensure that critical resources are available

Reducing the need for these buffers will require you to keep workers focused on one task at a time whenever possible. You must also create a smooth flow of work through and between workstations so that each chain of your operation is being utilized maximally. This means that each workstation has had its work simplified, and all the workstations have been ordered and arranged in such a way that the next step is fed and excess work in process inventory isn’t piling up between them.

Below, we will discuss how labor can help you attack all three types of buffers to increase your output and reduce lead times.

How labor fits into your critical chain

As you’re likely aware, labor is a critical resource. When you have too few or even too many workers, it creates problems for your operation.

Within the critical chain project management approach, many operations have to increase resource buffers due to a lack of available labor. They also end up increasing their project buffers to account for production delays due to their most specialized workers being assigned to multiple tasks instead of just their specialty.

Luckily, a more flexible approach to labor is within reach. With on-demand labor, you can reduce or even eliminate your resource buffer for labor, because it gives you access to infinite, flexible capacity.

How you can reduce buffers with on-demand labor

Labor is considered a critical resource in critical chain project management. That means addressing labor constraints by using on-demand labor directly eliminates the need for resource buffers to account for labor.

On-demand labor can also reduce the need for feeding buffers by increasing output on the feeding chains as quickly as needed. When you can instantly flex your capacity, you won’t have to wonder if the feeding chains will have enough workers to keep up with your critical chain.

By eliminating the need for labor resource buffers and reducing the need for feeding buffers, on-demand labor reduces your overall project buffer. If your whole operation can produce more, and do it consistently, you will be able to shorten lead times.

That’s because in critical chain project management, the amount of time workers need to complete each task on the line is used to calculate the overall project buffer.

This is done by finding your average cycle time for each step of the process on your critical chain. This will give you a baseline so you can get started on driving out variation. You have to identify how much variation there is before you can attack it, so for a few days you should record how much variation there is for each step of your process.

To find your project buffer, you sum all the expected variation for each step of the process on your critical chain into one big buffer placed at the end of the project.

The project buffer leaves you flexibility in your overall project, because if one task takes longer and you see that you are getting closer to your deadline, you can bring in extra help to get back on track before you devour your project buffer.

Since you’ll be able to eliminate task switching for your specialized workers and increase output at every step of your process with on-demand labor, your project buffer will inevitably dwindle.

Getting started with on-demand labor

To increase output from each chain and reduce your buffers with on-demand labor, getting started is as simple as signing up for a free business profile with Veryable.

Previous Posts

Traditional Staffing in Industrial Operations: What It Is and When It Works

The Future of Manufacturing and Logistics

Create a free business profile today to explore our platform.